Upgrades For Speed

Developed and designed entirely by CeramicSpeed the Oversized Pulley Wheel System for Campagnolo is advanced for the optimization of bike performance. Everything from bearings to the cage is made from the highest quality materials. The oversized aluminium pulley wheels are fitted with standard or coated CeramicSpeed Bearings, which reduce friction to the minimum.

The 13/19-tooth OSPW for Campagnolo privides a 40% lower friction over a standard 11-tooth Campagnolo pulley wheel and fits up to a 32-tooth cassette.

CeramicSpeed OSPW for Campagnolo is compatible with Record mechanical, Record EPS, Super Record mechanical, Super Record EPS, Chorus mechanical and Potenza mechanical.

IMPORTANT: When travelling, please remember to dismount your entire rear derailleur with an Allen key, as the OSPW System will not fit in most bike travel bags and could be damaged if left on.

For correct mounting of the product, please find a manual and video here.

Regarding the maintenance of your OSPW System, it is important that you properly lubricate your bearings in order to ensure optimal performance and maximum longevity. Add oil by using the lubrication points on the back cage plate, so that oil can penetrate the bearing. Do this when you lubricate your chain, if you have washed your bike or after riding in wet or muddy conditions.

Lightweight 3D printed hollow oversize pulley wheels for Shimano Ultegra/Dura Ace (6800/7800/7900/7970/9000/9070), SRAM Red/Force/Rival/Apex, both 10s and 11s, electronical and mechanical (17/17-tooth), Shimano 8000/9100 series (13/19-tooth) and Campagnolo.

The combination of 3D printed titanium oversized pulley wheels and coated CeramicSpeed Bearings result in the best pulley wheels in the world. Since the pulley wheels are the fastest spinning bearings on your bike, this CeramicSpeed upgrade is the most effective way to save energy or improve your time

Designed for top performance on off-road Shimano XT/XTR derailleurs, these pulley wheels are developed to have a longer lifetime, even in the conditions provided by MTB riding, and deliver less friction. Thanks to the high-quality components CeramicSpeed uses, these pulleys are resistant to impact and perform at their best when going off-road. For extra protection when riding in wet and muddy weather, we recommend you to use the CeramicSpeed LongLife Grease instead of Oil.

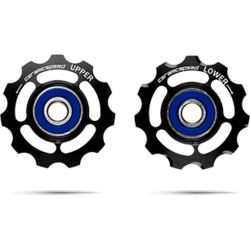

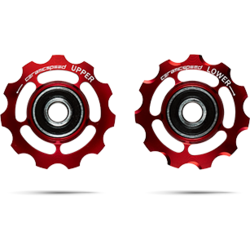

Aluminium Pulley Wheels

Manufactured from a lightweight alluminium alloy, these CeramicSpeed Pulley Wheels are guaranteed to optimise your drivetrain efficiency whatever your off-road discipline.

The CeramicSpeed UFO Racing Chains are for all riders that want to save between 2-5 watts on competition day. As a result of a special formula and in-house performance testing, the CeramicSpeed UFO Racing Chains now comes in two versions: an optimized KMC SL 11s and 10s chain which is compatible with SRAM, Campagnolo and Shimano, and an optimized Dura-Ace HG901 11s chain specific to Shimano drivetrains.

The CeramicSpeed UFO Racing Chains are developed for unmatched racing performance and are intended for race-day applications. The racing chains will last min. 600 km / 370 miles before significant efficiency losses, and potentially even longer under clean riding conditions. The latest frictional tests show that CeramicSpeed UFO Chains are the fastest, most reliable treated chains on the market.

To learn more about the UFO Racing Chain treatment and developing, please read this.

Be aware that the UFO treatment is not optimised for wet and muddy conditions, which might cause corrosion on the chain. Read more about maintenance here.

Testing results show, that UFO Racing Chain proves to be faster than other treated chains.

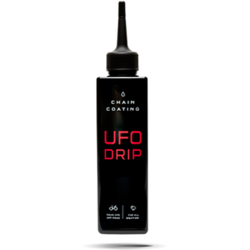

UFO Drip Chain Coating is a bottled product for chains that is applied in liquid form but which hardens to a 100% dry chain coating. It generates less friction than any other chain lube on the market (being out-performed only by the factory-treated UFO Racing Chain).

The genius of UFO Drip Chain Coating is that it combines the convenience of a drip application with the friction-beating performance of a completely dry chain coating. So, not only does UFO Drip test faster than every other chain lubricant, it's properties actually rank it in a brand-new category: the liquid-applied but ultimately 100% dry chain coating.

Another benefit of UFO Drip Chain Coating is the fact that the coating closes around the chain in a way that prevents all kinds of contamination your chain is exposed to when riding, from sticking to the chain. Therefore, make sure to clean your chain properly before applying UFO Drip, and it will then remain clean as long as you continously apply UFO Drip every 200 km as recommended.

Find instructions on how to clean your chain and apply UFO Drip Chain Coating here.

To learn more about the test results and how this product has been developed, please find all data at CeramicSpeed.com

Developed and designed entirely by CeramicSpeed, the Oversized Pulley Wheel System for Shimano is advanced for the optimization of bike performance. Everything from bearings to the cage is made from the highest quality materials. The oversized aluminium pulley wheels are fitted with standard or coated CeramicSpeed Bearings, which reduce friction to the minimum. The overall power savings of the OSPW System for Shimano reach 30%-60% or more in some cases. The OSPW System has a lifetime that lasts 3-5 times longer than the commonly used standard pulleys on the market. The OSPW System for Shimano comes as two different systems, one compatible with Ultegra (6700/6770/6800/6870) and Dura Ace (7900/7970/9000/9070), 10s and 11s, electric and mechanical groupsets, and another compatible with the Shimano 9100/9150 and 8000 series - EXCEPT the R8000 GS. While the first option features a set of two 17-tooth pulleys, the OSPW System for Shimano 9100/9150 and 8000 features an optimal 13/19-tooth combination specially developed to fit the design of the derailleur.

Find a list of compatability for OSPW for Shimano 9100/91500 and 8000 series here

IMPORTANT: When travelling, please remember to dismount your entire rear derailleur with an Allen key, as the OSPW System will not fit in most bike travel bags and could be damged if left on.

The revolutionary OSPW System is developed, produced and assembled by hand in Denmark. The product is the result of an in-depth development process and has been designed for optimal performance. Like all other products delivered by CeramicSpeed, OSPW System has also undergone a thorough test program. We are proud to say that professional triathletes such as Tim Don and Tyler Butterfield have great feedback for the system and, along with Pro Continental teams, they have made it a permanent part of their equipment.

Check out the FAQ page for more details about the OSPW System.

Regarding the maintenance of your OSPW System, it is important that you properly lubricate your bearings in order to ensure optimal performance and maximum longevity. Add oil by using the lubrication points on the back cage plate, so that oil can penetrate the bearing. Do this when you lubricate your chain, if you have washed your bike or after riding in wet or muddy conditions.

Entirely developed, designed and produced in Denmark by CeramicSpeed, the Oversized Pulley Wheel System for SRAM is a technologic advance for the cycling industry. Matching the highest quality materials with a unique design, the OSPW System delivers lower friction and longer lifetime, improving your competitive advantage. Thanks to the OSPW System for SRAM, the power savings start at 40%, and the CeramicSpeed Bearing inside guarantee a 3-5 times longer lifetime and commonly used standard pulleys on the market. The watt savings with a CeramicSpeed OSPW System for SRAM start at 1.6 watts and up.

IMPORTANT: When travelling, please remember to dismount your entire rear derailleur with an Allen key, as the OSPW System will not fit in most bike travel bags and could be damaged if left on.

Produced and assembled by hand in Denmark, the OSPW System has been developed to deliver optimal riding properties for either road, off-road or triathlon applications. Tested both on the road and in the lab, like all other CeramicSpeed products, the OSPW System for SRAM is proven to be better. Both professional triathletes as well as road teams have already chosen the OSPW System as a permanent part of their racing equipment convinced by the product properties.

Check out the FAQ page for more details about the OSPW System.

Remember to lubricate your CeramicSpeed Bearings properly in order to obtatin the optimal performance and the maximum longevity. When lubricating the chain, when washing your bike or after riding in wet/muddy conditions, it is recommended to lubricate the system’s bearings. To do so, add oil into the lubrication points on the back cage plate, so that oil can penetrate the bearing.

A world premiere and technological innovation, these hollow 3D printed titanium pulley wheels are 5-10% lighter than our original titanium Pulley Wheels and guarantee the same unparalleled lifetime and reduced friction.

The combination of 3D printed titanium pulley wheels and coated CeramicSpeed Bearings result in the best pulley wheels in the world. Since the pulley wheels are the fastest spinning bearings on your bike, this CeramicSpeed upgrade is the most effective way to save energy or improve your time.

The 3D printed titanium pulley wheels are extremely resistant to wear. This makes them a great choice if you ride in demanding conditions or just ride a lot. To give even greater protection and reduced friction, a super thin (2 microns) protective coating is applied to the bearing races. This further increases the resistance of the bearing to corrosion or damage from foreign objects.

Compatible for all Shimano 11-speed rear derailleurs, including Shimano 9100-series rear derailleurs.

Mounting and maintenance

Just like every other bearing system, it is important that these pulley wheels are correctly mounted and maintained. For mounting instructions, watch this installation video. Maintain your pulley wheels periodically by adding oil to the outside of the bearing seal, so that oil can penetrate the bearing. This is recommended when you lubricate your chain, after cleaning your bike, or after riding in wet or muddy conditions. For further maintenance instructions, please watch this video.

Do you want to know more about the development of these pulley wheels? Read more about it here.

The CeramicSpeed Eagle 14 Pulley Wheels have been designed to provide race precision shift performance and maximum drivetrain efficiency. Developed in partnership with Specialized S-Racing, CeramicSpeed Eagle 14 Pulley Wheels are the ideal substitute for SRAM factory standard pulley wheels, improving efficiency by 34.4% through a unique 14-tooth narrow-wide design.

The Eagle 14 Pulley Wheels are designed as 14/14-tooth pulleys to obtain better shifting and less chain friction. The narrow-wide design adds further shifting performance and increased life time.

The bearing race in the non-coated Eagle 14 Pulley Wheels is made of stainless steel to obtain even higher corrosion resistance and increased life time despite dirty riding conditions.

Aluminium Pulley Wheels

These aluminum alloy pulley wheels deliver a unique mix between low friction and long lifetime improving your performance when riding off-road with your SRAM Eagle 12-speed groupset.

Titanium Pulley Wheels

The Eagle 14 Pulley Wheels are available with CeramicSpeed Coated Bearings, which features increased resistance to corrosion and the damaging effects of contaminating factors like water, salt, or dirt are eliminated. This is thanks to a special coating applied to the bearing’s races, which is 75% harder than hardened steel.

Upgrade your SRAM XX1/X01 rear derailleur with CeramicSpeed Pulley Wheels for reduced friction and extended lifetime. A breakthrough for SRAM’s MTB systems, the XX1 and X01 rear derailleurs included new tooth designs for both pulley wheels. Because of our commitment to compatibility, we have designed specific pulley wheels that function perfectly as upgrade replacements for the MTB 1x11 SRAM systems.

Aluminium Pulley Wheels

These aluminum alloy pulley wheels deliver a unique mix between low friction and long lifetime improving your performance when riding off-road with your favourite SRAM XX1 or X01 system.

Titanium Pulley Wheels

When it comes to the ultimate pulley wheels for off-road applications, the SRAM 1-11 titanium pulley wheels are by far the most efficient. Available with CeramicSpeed coated bearings, these pulley wheels feature increased resistance to corrosion, and the damaging effects of contaminating factors like water, salt, or dirt are eliminated. This is thanks to a special coating applied to the bearing’s races, which is 75% harder than hardened steel.

In a friction test conducted by independent test lab Friction Facts, the CeramicSpeed Pulley Wheels came through as the lowest friction pulley wheels from a total of 19 market standards. See the complete results here.

Mounting and maintenance

It is very important to install and service these pulley wheels accordingly. Follow the video instructions for mounting of SRAM pulley wheels here. Maintenance is also required periodically. We recommend that you service your pulley wheels whenever you lubricate your chain, after washing your bike, or after riding in wet or muddy conditions. To do so, add CeramicSpeed Oil to the outside of the bearing seal, so that the oil can penetrate the bearing.

Upgrade your Shimano rear derailleur with CeramicSpeed Pulley Wheels for reduced friction and extended lifetime. The pulley wheels are the fastest spinning bearings on your bike, making an upgrade to CeramicSpeed an effective way to save energy. CeramicSpeed Pulley Wheels can be used for all cycling disciplines, and will last longer than any standard pulley wheels. The CeramicSpeed Pulley Wheels for Shimano rear derailleurs are specially designed to reduce friction to an absolute minimum, virtually eliminating the drag associated with standard pulley wheels.

Compatible for all Shimano 11-speed rear derailleurs, including Shimano 9100-series rear derailleurs.

Aluminium Pulley Wheels

These pulley wheels are made from a light Aluminium alloy that guarantees top performance, whatever your riding discipline. All components of our pulley wheels are of the highest quality, ensuring the best results.

Titanium Pulley Wheels

To benefit from the ultimate pulley wheels when it comes to wear and tear, we have introduced the titanium pulley wheels, which are extremely resistant to wear. This makes them a great choice if you ride in demanding conditions – for example off-road, in wet or otherwise corrosive environments. The titanium pulley wheels are also available with coated bearings to reduce friction and prolong lifetime even further.

The coated bearings are treated with a super thin (2 microns) protective layer that is applied to the bearing races. This increases the resistance of the bearing to corrosion even further, acting as a shield against the damage from foreign objects. Combining coated bearing races with a titanium pulley wheel creates a pulley wheel with extreme properties in terms of wear resistance and performance.

In a test effectuated by Friction Facts, CeramicSpeed scored 0.033w, while Shimano Acera registered 1.370. With these results, the benefits are evident. See the test results here.

To make sure that the pulley wheels perform at their best, it is important that your new pulley wheels are mounted correctly. Our videos will guide you through the process. *It is important that you properly lubricate your bearings in order to ensure optimum performance and maximum longevity. Add oil to the outside of the bearing seal, so the oil can penetrate the bearing. Maintenance for your CeramicSpeed Pulley Wheels is recommended every time you lubricate your chain, wash your bike, or after riding in wet or muddy conditions.

Page 1 of 1